Gas turbine engines are used in avionics, marine propulsion, heavy industries, and other applications. But when it comes to aircraft, gas turbines provide their power through the compressor section. Compressors are responsible for pulling air into the engine and squeezing it from high pressure to low pressure. The power generated from this is transferred to the next component: the turbine. To help with understanding what would happen if something went wrong with your gas turbine, you can read this blog article for more information!

What Is A Gas Turbine?

A gas turbine is a type of internal combustion engine that uses natural gas or other gaseous fuels to generate power. Turbines are more efficient than piston engines and can operate at higher speeds. Gas turbines are used in a variety of applications, including power generation, aircraft propulsion, and ships.

Gas turbines work by compressing air and mixing it with fuel that is combusted within the engine. The hot gases from combustion expand through a turbine, which drives an electric generator or a compressor. The exhaust from the turbine is used to power a second turbine in what is known as a turboprop engine. In a jet engine, the exhaust is ejected at high velocity to provide thrust.

Gas turbines are highly efficient and can reach thermal efficiencies of 40-50%. They are also relatively compact and lightweight, making them ideal for use in mobile applications such as aircraft and ships. However, gas turbines require regular maintenance and repair in order to keep them running properly.

How Does The Turbine Work?

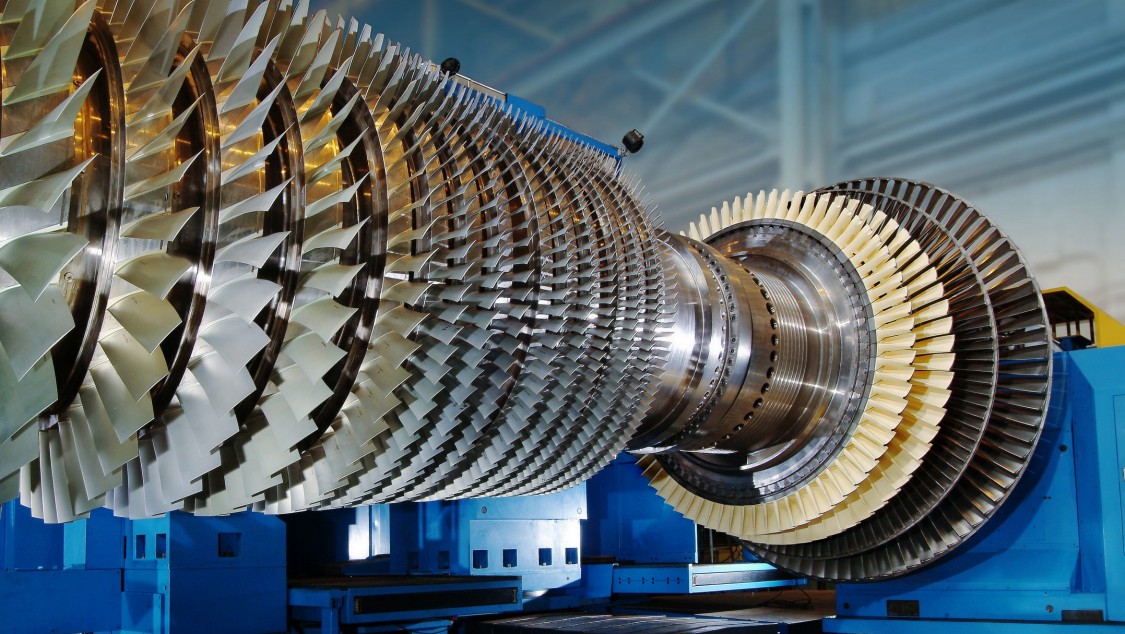

The turbine is the key component of a gas turbine engine, and its function is to convert the energy in the combustion gases into mechanical energy that can be used to power an aircraft or other vehicle. The turbine works by redirecting the hot exhaust gases from the engine’s combustion chamber through a series of blades that spin at high speeds. This rotation creates torque that turns an attached shaft, which in turn powers the compressor, generator, or other devices that are connected to the shaft.

The turbine must be able to withstand the extreme temperatures and pressures of the exhaust gases, as well as the forces exerted on it by the spinning blades. To do this, it is made from materials such as high-strength steel and titanium alloys. Gas turbine repair is essential to keep these engines operating properly and to ensure that they can continue to generate the power needed for flight.

Types of Gas Turbines

There are three main types of gas turbines: axial-flow, radial, and mixed-flow turbines:

Axial-flow gas turbines have their blades mounted on a shaft that runs parallel to the axis of rotation. The hot gases flow through the blades in an axial direction, which gives these turbines their name.

Radial gas turbines have blades mounted on a shaft that is perpendicular to the axis of rotation. The hot gases flow through the blades in a radial direction.

Mixed-flow gas turbines have both an axial component and a radial component to their blade design.

All three types of gas turbines work by compressing air with rotating blades. The compressed air is then mixed with fuel and combusted. The hot gases from combustion expand through the turbine blades, causing them to rotate. This rotation turns a generator, which produces electricity.

The Importance of Gas Turbine Repair:

As the world progresses, our reliance on technology increases. One of the most important pieces of technology in our modern world is the gas turbine. Gas turbines are used in a variety of applications, from powering airplanes to generating electricity.

While gas turbines are incredibly reliable, they do require occasional repair and maintenance. The Importance of Gas Turbine Repair is two-fold: First, to keep the turbine running properly, and second, to prevent unscheduled downtime which can be costly.

Gas turbine repair can be divided into two main categories: hot-section repairs and cold-section repairs. Hot section repairs involve any component of the gas turbine that experiences high temperatures during operation, such as the combustion chamber or turbine blades. Cold section repairs include any component that does not experience high temperatures during operation, such as the compressor or fuel system.

Both hot and cold section repairs are important for keeping your gas turbine running properly. However, hot section repairs are generally more critical because they can directly affect the performance of the gas turbine. That being said, it is important to have a qualified technician perform all gas turbine repairs, regardless of whether they are classified as hot or cold section repairs.

If you are looking for a qualified technician to perform gas turbine repair, look no further than Allied PG. Our team of highly trained and certified gas turbine technicians is an expert in all aspects of gas turbine repair, from hot section repairs to cold section repairs. Contact us today to schedule a free consultation.

Why Do Turbines Break Down?

The most common causes of gas turbine breakdowns are:

- Exhaust leaks.

- Fuel system issues.

- Ignition system problems.

- Lubrication system failure.

When any of these systems fail, it can cause the gas turbine to break down. Exhaust leaks are the most common cause of gas turbine breakdowns. If there is an exhaust leak, it can allow hot gases to escape from the turbine. This can damage the turbine blades and cause the turbine to shut down.

Fuel system issues can also cause gas turbines to break down. If the fuel system is not working properly, it can cause the turbine to run lean. This can damage the turbine and cause it to shut down.

Ignition system problems can also cause gas turbines to break down. If the ignition system is not working properly, it can prevent the turbine from starting up. Additionally, if the ignition system fails while the turbine is running, it can cause the turbine to shut down abruptly.

Finally, lubrication system failure can lead to gas turbine breakdowns. If the lubrication system fails, it can cause friction between moving parts in the turbine. This friction can damage parts of the turbine and eventually lead to shutdowns.

How To Prevent Breakdowns:

The most important part of gas turbine repair is preventing breakdowns from happening in the first place.

There are several things that can be done to prevent problems:

Regularly inspect and maintain the gas turbine. This includes checking for wear and tear, as well as making sure all parts are properly lubricated.

- Keep the work environment clean and free of debris.

- Make sure only qualified personnel are working on the gas turbine.

- Follow the manufacturer’s instructions for operation and maintenance.